Table of contents

We shall now see how to derive the generalized Hooke's law, starting from the 1D case, we have Hooke's law.

σ x = E ε x \sigma_x =E\varepsilon_x σ x = E ε x Now, in 2D any strain in one direction gives rise to another strain in the orthogonal direction. This is known as the transversal strain. For small strains, the transversal strain is given by

ε y = − ν ε x \varepsilon_y =-\nu \varepsilon_x ε y = − ν ε x where ν \nu ν

ν = − d ε y d ε x \nu =-\dfrac{d\varepsilon_y }{d\varepsilon_x } ν = − d ε x d ε y Typical values for the Poisson's ratio:

Material Poisson's ratio Rubber 0.4999 Aluminium 0.32 Steel 0.27-0.33 Cork 0.0

For 3D we get

ε x = σ x E − ν ( σ y E + σ z E ) ε y = σ y E − ν ( σ x E + σ z E ) ε z = σ z E − ν ( σ x E + σ y E ) } [ ε x ε y ε z ] = 1 E [ 1 − ν − ν − ν 1 − ν − ν − ν 1 ] [ σ x σ y σ z ]

\def\arraystretch{2.0}

\left.\begin{array}{c}

\varepsilon_x =\dfrac{\sigma_x }{E}-\nu \left(\dfrac{\sigma_y }{E}+\dfrac{\sigma_z }{E}\right)\\

\varepsilon_y =\dfrac{\sigma_y }{E}-\nu \left(\dfrac{\sigma_x }{E}+\dfrac{\sigma_z }{E}\right)\\

\varepsilon_z =\dfrac{\sigma_z }{E}-\nu \left(\dfrac{\sigma_x }{E}+\dfrac{\sigma_y }{E}\right)

\end{array}\right\rbrace \left\lbrack \begin{array}{c}

\varepsilon_x \\

\varepsilon_y \\

\varepsilon_z

\end{array}\right\rbrack =\dfrac{1}{E}\left\lbrack \begin{array}{ccc}

1 & -\nu & -\nu \\

-\nu & 1 & -\nu \\

-\nu & -\nu & 1

\end{array}\right\rbrack \left\lbrack \begin{array}{c}

\sigma_x \\

\sigma_y \\

\sigma_z

\end{array}\right\rbrack

ε x = E σ x − ν ( E σ y + E σ z ) ε y = E σ y − ν ( E σ x + E σ z ) ε z = E σ z − ν ( E σ x + E σ y ) ⎭ ⎬ ⎫ ⎣ ⎡ ε x ε y ε z ⎦ ⎤ = E 1 ⎣ ⎡ 1 − ν − ν − ν 1 − ν − ν − ν 1 ⎦ ⎤ ⎣ ⎡ σ x σ y σ z ⎦ ⎤ This system can be inverted, yielding

σ x = E 1 + ν ( ε x + ν 1 + 2 ν ( ε x + ε y + ε z ) ) σ y = E 1 + ν ( ε y + ν 1 + 2 ν ( ε x + ε y + ε z ) ) σ z = E 1 + ν ( ε z + ν 1 + 2 ν ( ε x + ε y + ε z ) )

\def\arraystretch{2.0}

\begin{array}{l}

\sigma_x =\dfrac{E}{1+\nu }\left(\varepsilon_x +\dfrac{\nu }{1+2\nu }\left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)\right)\\

\sigma_y =\dfrac{E}{1+\nu }\left(\varepsilon_y +\dfrac{\nu }{1+2\nu }\left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)\right)\\

\sigma_z =\dfrac{E}{1+\nu }\left(\varepsilon_z +\dfrac{\nu }{1+2\nu }\left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)\right)

\end{array}

σ x = 1 + ν E ( ε x + 1 + 2 ν ν ( ε x + ε y + ε z ) ) σ y = 1 + ν E ( ε y + 1 + 2 ν ν ( ε x + ε y + ε z ) ) σ z = 1 + ν E ( ε z + 1 + 2 ν ν ( ε x + ε y + ε z ) ) The bulk modulus, K K K

K = σ m Δ K=\dfrac{\sigma_m }{\Delta } K = Δ σ m using Δ = ε x + ε y + ε z \Delta =\varepsilon_x +\varepsilon_y +\varepsilon_z Δ = ε x + ε y + ε z

we get

Δ = 1 − 2 ν E ( σ x + σ y + σ z ) \Delta =\dfrac{1-2\nu }{E}\left(\sigma_x +\sigma_y +\sigma_z \right) Δ = E 1 − 2 ν ( σ x + σ y + σ z ) under the same pressure we have

σ x + σ y + σ z = 3 σ m \sigma_x +\sigma_y +\sigma_z =3\sigma_m σ x + σ y + σ z = 3 σ m and thus

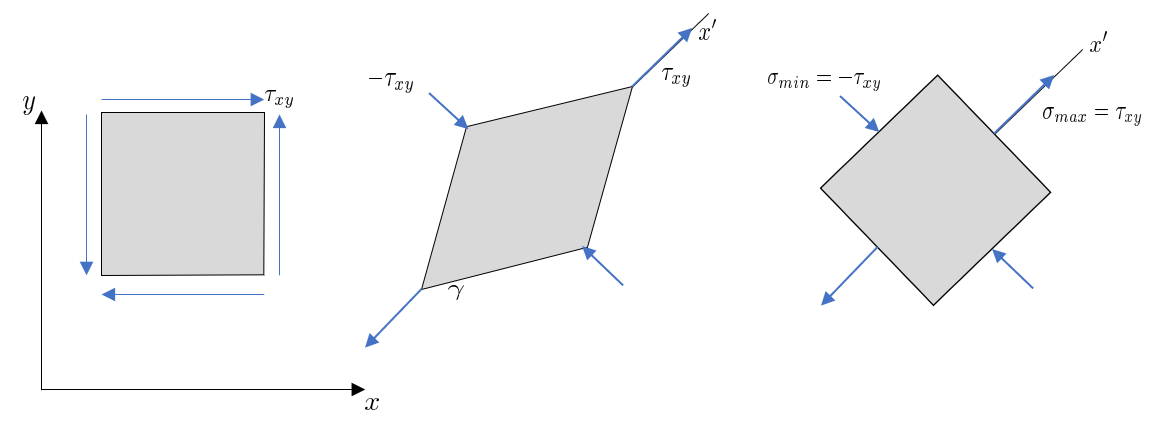

K = σ m Δ = E 3 ( 1 − 2 ν ) K=\dfrac{\sigma_m }{\Delta }=\dfrac{E}{3\left(1-2\nu \right)} K = Δ σ m = 3 ( 1 − 2 ν ) E Consider an element under pure shear. We can rotate this element such that the shear stresses align with the principal stresses.

σ max = σ 1 = τ x y \sigma_{\max } =\sigma_1 =\tau_{x\;y} σ m a x = σ 1 = τ x y σ min = σ 2 = − τ x y \sigma_{\min } =\sigma_2 =-\tau_{x\;y} σ m i n = σ 2 = − τ x y

We can substitute the normal stresses with principal stresses, σ x = σ max , σ y = σ min , σ z = 0 \sigma_x =\sigma_{\max } ,\sigma_y =\sigma_{\min } ,\sigma_z =0 σ x = σ m a x , σ y = σ m i n , σ z = 0

ε x = σ x E − ν ( σ y E + σ z E ) = ε max = τ x y E − ν ( − τ E + 0 ) ⇒ ε max = τ x y E ( 1 + ν ) \begin{array}{l}

\varepsilon_x =\dfrac{\sigma_x }{E}-\nu \left(\dfrac{\sigma_y }{E}+\dfrac{\sigma_z }{E}\right)=\varepsilon_{\max } =\dfrac{\tau_{x\;y} }{E}-\nu \left(\dfrac{-\tau }{E}+0\right)\\

\Rightarrow \varepsilon_{\max } =\dfrac{\tau_{x\;y} }{E}\left(1+\nu \right)

\end{array} ε x = E σ x − ν ( E σ y + E σ z ) = ε m a x = E τ x y − ν ( E − τ + 0 ) ⇒ ε m a x = E τ x y ( 1 + ν ) Similar to the principal stresses, we can get the principal strains

ε 1 , 2 = ε x + ε y 2 ± ( ε x + ε y 2 ) 2 + ( γ x y 2 ) 2 \varepsilon_{1,2} =\dfrac{\varepsilon_x +\varepsilon_y }{2}\pm \sqrt{ {\left(\dfrac{\varepsilon_x +\varepsilon_y }{2}\right)}^2 +{\left(\dfrac{\gamma_{x\;y} }{2}\right)}^2 } ε 1 , 2 = 2 ε x + ε y ± ( 2 ε x + ε y ) 2 + ( 2 γ x y ) 2 and in the principal direction we have ε x = ε y = 0 \varepsilon_x =\varepsilon_y =0 ε x = ε y = 0

and thus the strain in the principal direction is

ε max = ε 1 = γ x y 2 \varepsilon_{\max } =\varepsilon_1 =\dfrac{\gamma_{x\;y} }{2} ε m a x = ε 1 = 2 γ x y Hooke's law for shearing states that

τ x y = G γ x y \tau_{x\;y} =G\gamma_{x\;y} τ x y = G γ x y So we get ε max = τ x y 2 G \varepsilon_{\max } =\frac{\tau_{x\;y} }{2G} ε m a x = 2 G τ x y

G = E 2 ( 1 + ν ) G=\dfrac{E}{2\left(1+\nu \right)} G = 2 ( 1 + ν ) E In general we have ε = τ x y 2 G \varepsilon =\frac{\tau_{x\;y} }{2G} ε = 2 G τ x y

ε x y = ( 1 + ν ) τ x y E \varepsilon_{x\;y} =\left(1+\nu \right)\dfrac{\tau_{x\;y} }{E} ε x y = ( 1 + ν ) E τ x y and

τ x y = E 1 + ν ε x y \tau_{x\;y} =\dfrac{E}{1+\nu }\varepsilon_{x\;y} τ x y = 1 + ν E ε x y Since earlier we have

σ x = E 1 + ν ( ε x + ν 1 + 2 ν ( ε x + ε y + ε z ) ) \sigma_x =\dfrac{E}{1+\nu }\left(\varepsilon_x +\dfrac{\nu }{1+2\nu }\left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)\right) σ x = 1 + ν E ( ε x + 1 + 2 ν ν ( ε x + ε y + ε z ) ) which when expanded becomes

σ x = ( E 1 + ν ⏟ 2 μ = 2 G ε x + E ν ( 1 + ν ) ( 1 + 2 ν ) ⏟ λ ( ε x + ε y + ε z ) ) \sigma_x =\left(\underset{2\mu =2G}{\underbrace{\dfrac{E}{1+\nu } } } \varepsilon_x +\underset{\lambda }{\underbrace{\dfrac{E\nu }{\left(1+\nu \right)\left(1+2\nu \right)} } } \left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)\right) σ x = ⎝ ⎛ 2 μ = 2 G 1 + ν E ε x + λ ( 1 + ν ) ( 1 + 2 ν ) E ν ( ε x + ε y + ε z ) ⎠ ⎞ we recognize, in the first term, the shear modulus G G G μ \mu μ λ \lambda λ λ \lambda λ μ \mu μ

[ σ x τ x y τ x z τ x y σ y τ y z τ x z τ y z σ z ] = 2 μ [ ε x ε x y ε x z ε x y ε y ε y z ε x z ε y z ε z ] + λ [ 1 0 0 0 1 0 0 0 1 ] ⏟ I ( ε x + ε y + ε z ) ⏟ t r ε = ∇ ⋅ u \left\lbrack \begin{array}{ccc}

\sigma_x & \tau_{x\;y} & \tau_{x\;z} \\

\tau_{x\;y} & \sigma_y & \tau_{y\;z} \\

\tau_{x\;z} & \tau_{y\;z} & \sigma_z

\end{array}\right\rbrack =2\mu \left\lbrack \begin{array}{ccc}

\varepsilon_x & \varepsilon_{x\;y} & \varepsilon_{x\;z} \\

\varepsilon_{x\;y} & \varepsilon_y & \varepsilon_{y\;z} \\

\varepsilon_{x\;z} & \varepsilon_{y\;z} & \varepsilon_z

\end{array}\right\rbrack +\lambda \underset{\bm I }{\underbrace{\left\lbrack \begin{array}{ccc}

1 & 0 & 0\\

0 & 1 & 0\\

0 & 0 & 1

\end{array}\right\rbrack } } \underset{\mathrm{tr} \bm \varepsilon =\nabla \cdot \bm u }{\underbrace{\left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right)} } ⎣ ⎡ σ x τ x y τ x z τ x y σ y τ y z τ x z τ y z σ z ⎦ ⎤ = 2 μ ⎣ ⎡ ε x ε x y ε x z ε x y ε y ε y z ε x z ε y z ε z ⎦ ⎤ + λ I ⎣ ⎡ 1 0 0 0 1 0 0 0 1 ⎦ ⎤ tr ε = ∇ ⋅ u ( ε x + ε y + ε z ) A quick sanity check: σ y = 2 μ ε y + λ ( ε x + ε y + ε z ) \sigma_y =2\mu \varepsilon_y +\lambda \left(\varepsilon_x +\varepsilon_y +\varepsilon_z \right) σ y = 2 μ ε y + λ ( ε x + ε y + ε z ) τ x z = 2 μ ε x z \tau_{x\;z} =2\mu \varepsilon_{x\;z} τ x z = 2 μ ε x z

We arrive at the generalized Hooke's law for isotropic materials

σ = 2 μ ε + λ t r ε I or σ = 2 μ ε + λ ∇ ⋅ u I

\boxed{

\bm \sigma = 2\mu \bm \varepsilon + \lambda \mathrm{tr} \bm \varepsilon \bm I \quad \text{ or } \quad \bm \sigma = 2\mu \bm \varepsilon + \lambda \nabla \cdot \bm u \bm I

}

σ = 2 μ ε + λ tr ε I or σ = 2 μ ε + λ ∇ ⋅ u I Note that the notation for the shear modulus G G G μ \mu μ

The first term of the stress tensor is known as the deviatoric stress tensor and the second term is known as the volumetric stress tensor. The same goes for the strain tensor.

ε = 1 2 μ σ − λ 2 μ ( 3 λ + 2 μ ) t r σ I \bm \varepsilon =\dfrac{1}{2\mu } \bm \sigma -\dfrac{\lambda }{2\mu \left(3\lambda +2\mu \right)}\mathrm{tr} \bm \sigma \bm I ε = 2 μ 1 σ − 2 μ ( 3 λ + 2 μ ) λ tr σ I See the Efficient Engineer video on this topic.

Consider a cube with side length a a a

Δ V = V − V 0 ≈ a 3 ( 1 + ε x + ε y + ε z ) \Delta V=V-V_0 \approx a^3 \left(1+\varepsilon_x +\varepsilon_y +\varepsilon_z \right) Δ V = V − V 0 ≈ a 3 ( 1 + ε x + ε y + ε z ) where we identify the dilation of the volume as ε x + ε y + ε z = t r ε = : I 1 \varepsilon_x +\varepsilon_y +\varepsilon_z =\mathrm{tr} \bm \varepsilon =:I_1 ε x + ε y + ε z = tr ε =: I 1

Now, consider λ \lambda λ λ = E ν ( 1 + ν ) ( 1 + 2 ν ) \lambda =\frac{E\nu }{\left(1+\nu \right)\left(1+2\nu \right)} λ = ( 1 + ν ) ( 1 + 2 ν ) E ν ν → 1 / 2 \nu \to 1/2 ν → 1/2

λ → ∞ ⇒ f o r c i n g ε x + ε y + ε z → 0 \lambda \to \infty \overset{\mathrm{forcing} }{\Rightarrow} \varepsilon_x +\varepsilon_y +\varepsilon_z \to 0 λ → ∞ ⇒ forcing ε x + ε y + ε z → 0

Which means that the volume change tends to zero with the Poisson's ratio tending towards 0.5, meaning the material becomes incompressible.

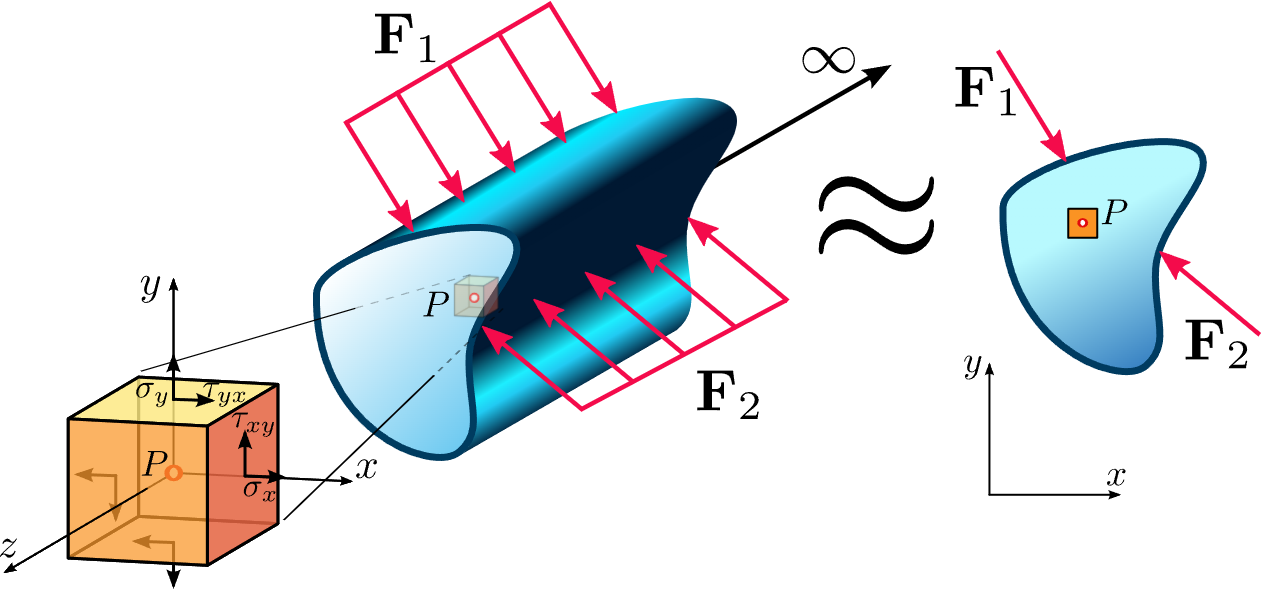

Many applications where the structure is much longer than its cross section can be approximated using a 2D simplification called plain strain . This greatly reduces the computational complexity of solving the resulting numerical problem.

For plain strain all strain components in the z − z- z − z − z- z −

[ ε x ε x y 0 ε x y ε x 0 0 0 0 ] \left\lbrack \begin{array}{ccc}

\varepsilon_x & \varepsilon_{x\;y} & 0\\

\varepsilon_{x\;y} & \varepsilon_x & 0\\

0 & 0 & 0

\end{array}\right\rbrack ⎣ ⎡ ε x ε x y 0 ε x y ε x 0 0 0 0 ⎦ ⎤ which gives

[ σ x σ x y 0 σ x y σ x 0 0 0 σ z ] \left\lbrack \begin{array}{ccc}

\sigma_x & \sigma_{x\;y} & 0\\

\sigma_{x\;y} & \sigma_x & 0\\

0 & 0 & \sigma_z

\end{array}\right\rbrack ⎣ ⎡ σ x σ x y 0 σ x y σ x 0 0 0 σ z ⎦ ⎤ The stress tensor has a non-zero z component due to: σ z = E 1 + ν ( 0 + ν 1 + 2 ν ( ε x + ε y ⏟ ≠ 0 + 0 ) ) \sigma_z =\frac{E}{1+\nu }\left(0+\frac{\nu }{1+2\nu }\left(\underset{\not= 0}{\underbrace{\varepsilon_x +\varepsilon_y } } +0\right)\right) σ z = 1 + ν E ⎝ ⎛ 0 + 1 + 2 ν ν ⎝ ⎛ = 0 ε x + ε y + 0 ⎠ ⎞ ⎠ ⎞

Hooke's law takes the form

[ σ x σ x y σ x y σ y ] = E 1 + ν ( [ ε x ε x y ε x y ε y ] + ν 1 + 2 ν [ 1 0 0 1 ] ( ε x + ε y ) ) \left\lbrack \begin{array}{cc}

\sigma_x & \sigma_{x\;y} \\

\sigma_{x\;y} & \sigma_y

\end{array}\right\rbrack =\dfrac{E}{1+\nu }\left(\left\lbrack \begin{array}{cc}

\varepsilon_x & \varepsilon_{x\;y} \\

\varepsilon_{x\;y} & \varepsilon_y

\end{array}\right\rbrack +\dfrac{\nu }{1+2\nu }\left\lbrack \begin{array}{cc}

1 & 0\\

0 & 1

\end{array}\right\rbrack \left(\varepsilon_x +\varepsilon_y \right)\right) [ σ x σ x y σ x y σ y ] = 1 + ν E ( [ ε x ε x y ε x y ε y ] + 1 + 2 ν ν [ 1 0 0 1 ] ( ε x + ε y ) ) with the Lamé parameters

λ = E ν ( 1 + ν ) ( 1 + 2 ν ) a n d μ = E 2 ( 1 + ν )

\boxed{

\lambda =\dfrac{E\nu }{\left(1+\nu \right)\left(1+2\nu \right)}\;\mathrm{and}\;\mu =\dfrac{E}{2\left(1+\nu \right)}

}

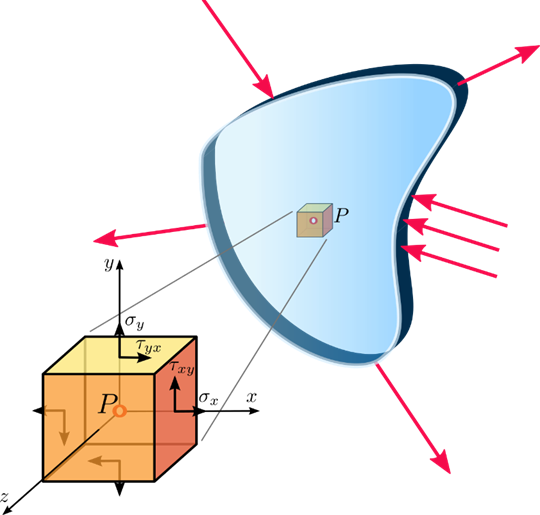

λ = ( 1 + ν ) ( 1 + 2 ν ) E ν and μ = 2 ( 1 + ν ) E For plane stress, we assume a very thin object that is loaded in-plane. No bending can occur in such a model. Typical applications are thin walled structures with edge loads, even very slightly curved geometry can assume plane stress, such as pressure vessels. This type of model is also called a plate. The stress can be simplified to

[ σ x σ x y 0 σ x y σ x 0 0 0 0 ] \left\lbrack \begin{array}{ccc}

\sigma_x & \sigma_{x\;y} & 0\\

\sigma_{x\;y} & \sigma_x & 0\\

0 & 0 & 0

\end{array}\right\rbrack ⎣ ⎡ σ x σ x y 0 σ x y σ x 0 0 0 0 ⎦ ⎤ effectively reducing the problem to a 2D problem.

Hooke's law takes the form

[ σ x σ x y σ x y σ y ] = E 1 − ν 2 ( ( 1 − ν ) [ ε x ε x y ε x y ε y ] + ν [ 1 0 0 1 ] ( ε x + ε y ) ) \left\lbrack \begin{array}{cc}

\sigma_x & \sigma_{x\;y} \\

\sigma_{x\;y} & \sigma_y

\end{array}\right\rbrack =\dfrac{E}{1-\nu^2 }\left(\left(1-\nu \right)\left\lbrack \begin{array}{cc}

\varepsilon_x & \varepsilon_{x\;y} \\

\varepsilon_{x\;y} & \varepsilon_y

\end{array}\right\rbrack +\nu \left\lbrack \begin{array}{cc}

1 & 0\\

0 & 1

\end{array}\right\rbrack \left(\varepsilon_x +\varepsilon_y \right)\right) [ σ x σ x y σ x y σ y ] = 1 − ν 2 E ( ( 1 − ν ) [ ε x ε x y ε x y ε y ] + ν [ 1 0 0 1 ] ( ε x + ε y ) ) In this case, the Lamé parameter become

λ = E ν 1 + ν 2 a n d μ = E 2 ( 1 + ν )

\boxed{

\lambda =\dfrac{E\nu }{1+\nu^2 }\;\mathrm{and}\;\mu =\dfrac{E}{2\left(1+\nu \right)}

}

λ = 1 + ν 2 E ν and μ = 2 ( 1 + ν ) E Note however that we have a non-zero strain component due to

ε z = 0 − ν ( σ x E + σ y E ) \varepsilon_z =0-\nu \left(\dfrac{\sigma_x }{E}+\dfrac{\sigma_y }{E}\right) ε z = 0 − ν ( E σ x + E σ y ) Make sure to check out The Efficient Engineers video on this topic